How To Choose Between Coated and Uncoated Blades

Whether you are a DIY enthusiast who is a proud owner of multi-master tool or a professional handyman that uses the oscillating tool on a daily basis, you will have been part of the long ongoing debate about pros and cons of using coated and uncoated blades. While professionals users prefer to use quality multi-tool blades, most DIY’s that use the tool prefer the inexpensive and sturdy aftermarket Fein saw blades that are as good as new.

Pros and cons of coated blades

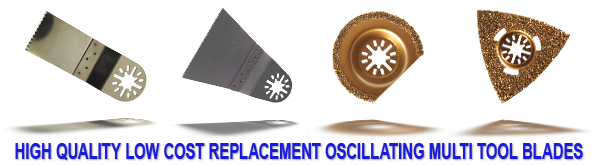

Though all blades are made of high-speed steel which is quite strong, it is consider softer than steel with high carbon content. These blades are used for cutting dense materials like hardwood and metal and tend to have large-toothed blades. Sometimes coatings of titanium, carbide and other materials are applied to strengthen the steel and increase its durability. The resilient coatings make the tooth edge harder so they do not break or get heated while cutting tough materials like wood and metal. As the coating is made of robust substances, the blades are more resistant to wear and tear like the specialty diamond multi tool blades, and they offer lesser resistance during use. The only two problems with coated blades are their high cost and significant weakening of the blade edge after the coating starts to wear away.

Pros and cons of uncoated blades

Uncoated blades are referred to as “naked blades” by professionals as these do not have a protective on their surface. These blades are made of varied materials beside high-speed steel like carbon alloys and titanium. A common reason why these multi-tool blades are preferred is that they can be sharpened again and again after every use to retain their sharp edge. They also cost less than a coated blade and offer minimal resistance during use. These blades create more friction and tend to make the tool heat up if excessive pressure is applied. As the steel blades are not coated these are softer and have to be used gently.