Cutting Metal with an Oscillating Multi-Tool

Several years ago, carbide-tipped blades were only used by professionals in jobs that required metal cutting. For instance, plumbers have often had to use a carbide-tipped oscillating multi-tool to cut off stubborn rusted nuts that refuses to come off with a wrench, or they've had to saw something off under the sink deck, where there's simply no room to maneuver. With a quality blade and an oscillating tool, some amazing tasks could be done - but only by professionals.

Carbide Tip Effectiveness

That has all changed for two basic reasons. First of all, the word is out now about how amazingly effective carbide-tipped blades can be for precise cuts, and how they will last at least 10 times longer than any other saw blade. Some carbide manufacturers claim that their blades last as much as 50 times longer than conventional steel-tipped blades, but pride notwithstanding, it is safe to say that the carbide blades have superior operational life.

The second reason for the new found popularity of carbide-tipped blades is that the price on them has come down considerably in the past five years, and they are now more affordable to home handymen and do-it-yourselfers. With the combination of superior performance and reasonable pricing, carbide-tipped blades have quickly become extremely popular.

Safety First

The first thing to remember about a carbide-tipped blade is that it should be handled with extreme caution, and this means much more than just the ordinary respect you'd have for a saw blade. The tiny little chips of tungsten carbide which form the tooth tips are extraordinarily sharp, and can easily rip the skin if not handled with care.

If these little chips have become dull with usage, they can be sharpened to their factory condition so they are again safe for operation, but most likely the average handyman will seldom encounter a dull carbide-tipped blade. In keeping with the safety theme, goggles or some kind of face mask should also be worn when cutting metal with a carbide-tipped blade, and blade guards should be installed to prevent accidents.

Operational Tips

Oscillating tools accomplish their task by vibrating back and forth so quickly that the eye cannot follow the motion, so they are always equipped with some kind of speed control mechanism. When making a cut on metal, the best approach is to start the oscillating tool on a relatively slow speed, until a cut or gouge has been applied to the surface being cut. That will provide a much better groove for the blade when it is increased to normal cutting speed.

If cutting through a rusted-on nut, you should only make your cut about three-quarters through the nut and retract the carbide-tipped blade. Then you can take a pair of pliers and twist off the nut manually, thereby avoiding the possibility of sending the nut flying up or down in an unsafe manner because of the high speed of the blade. That high speed vibration on the blade should always be borne in mind when using an oscillating tool.

One additional tip would be to make sure you are actually using quality equipment - just because it's a carbide-tipped blade does not mean it is of superior quality. Check to make sure you are purchasing a high quality blade, otherwise you may find that your 'high performance' blade doesn't really perform up to snuff.

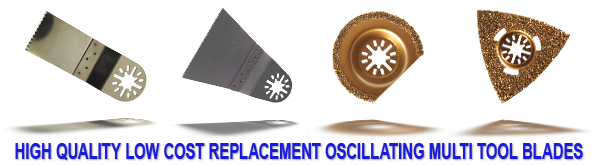

Make sure your every blade is tough enough to get the job done right by shopping for your replacement oscillating multi-tool blades and accessories at Fitz All Blades. Carrying the best quality of replacement blades and accessories from top name brand manufacturers, Fitz All Blades is your one stop shop no matter if you’re looking for Fein Multimaster accessories or Chicago Multi-tool Blades. Make sure you have the right tool to finish the job and shop Fitz All Blades today!