Oscillating Multi Tool Flush Cut Blades for the Tight Squeeze

We all make mistakes. You might accidentally say something stupid on a first date, forget to buy milk at the grocery store (again), or cut that piece of wood a wee bit smaller than you were supposed to during your big DYI job. Unfortunately, in construction, a faulty cut can lead to wasted materials, shoddy makeup work, and extra dollars spent. And, more often than not, trying to fix the problem by stuffing a piece of material into the gap just makes it look worse.

We all make mistakes. You might accidentally say something stupid on a first date, forget to buy milk at the grocery store (again), or cut that piece of wood a wee bit smaller than you were supposed to during your big DYI job. Unfortunately, in construction, a faulty cut can lead to wasted materials, shoddy makeup work, and extra dollars spent. And, more often than not, trying to fix the problem by stuffing a piece of material into the gap just makes it look worse.

Enter the flush cut blade for oscillating multi tools. Think of these babies as erasers – they can correct measurement boo-boos with their precision slicing. Here’s why you shouldn’t start any construction project without one.

Just A Smidge

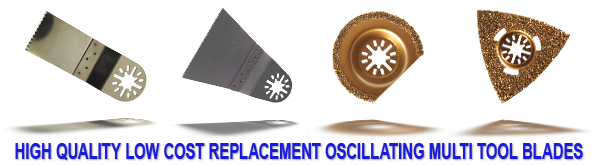

Flush cut tools are meant to be über precise. They have a partially circular shape with a razor-thin edge, which can be lightly serrated or even gritty depending on which one you choose. Whichever one you go with, though, flush cut blades are capable of shaving very thin pieces of material ranging from fiberglass to some metals. This makes them the ultimate blades for fixing mistakes.

Models

The base model for oscillating multi tool flush cut blades is the half moon blade. With its hundreds of tiny teeth, the half moon blade can cut through wood, cement board, plexiglass, and the like, not to mention some metals. This steel blade can be got for under $8 from replacement blade providers, making it an economical choice for all.

For those who are looking for something a little sharper, the flush cut diamond multi tool blade might be the way to go. Diamond, the hardest natural substance, will slice through rock – literally – as well as materials like cement and time. The diamond blade is meant to be kept wet during cutting and features a gritty, incredibly sharp edge. And, starting at $11 from blade replacement manufacturers, this diamond won’t exactly leave your wallet empty.

Filling In The Cracks

Oscillating multi tool flush cut blades can save the day on practically any project, and keeping one handy during construction projects can be the difference between success and disaster. Here are a few ideas on how to use this helpful blade.

Doors: It is common for doors to be a tad too short, leaving a wider-than-necessary gap between the floor and the edge of the door. This can be an economic disaster for outside doors, since temperature control literally leaks right out. It is also annoying for doors inside of a home, since more space under the door means more obnoxious music, private conversation, and other noises escaping from rooms.

Keep sound, heat, and other stuff where it is supposed to be by cutting a thin strip of wood with your flush cut blade and adding it to the underside of the door. For doors leading to the outside, you can go the extra mile and add an insulating strip if you don’t already have one.

Trim: Adding trim to rooms is a great way to give your home some extra pizazz, but it easy to miscalculate and end up with gaps in your trim. A flush cut blade is the tool of choice for cutting slivers to fill in these embarrassing holes for a truly professional-looking job. No one will ever know, especially if you slap a coat of paint on there.

Wobbly Chairs or Tables: Everyone has one of these – that terrible wobbly chair that no one ever wants to sit on, or even the dining room table that thumps to one side whenever you set down a heavy dish. Fix the problem once and for all by cutting a just-right slice of wood with a flush cut blade and adding it to that leg of the furniture. Voilá! Now all you have to do is throw away the magazine you had stuffed under the table leg for so long.

Oscillating multi tool flush cut blades can fill in any gap with speed and ease. So, the next time you undershoot and cut something just a bit too short, be sure to have a flush cut blade at the ready.

Image source: http://www.sxc.hu/assets/182935/1829348312/carpenter-824010-m.jpg