What's the best blade for my task?

An oscillating multi tool is a versatile and essential tool for any DIY enthusiast or professional contractor. It can be used for a variety of tasks, from cutting and sanding to scraping and grinding. One of the most important components of an oscillating multi tool is its blade. In this blog post, we will take a closer look at oscillating multi tool blades and discuss the different types available.

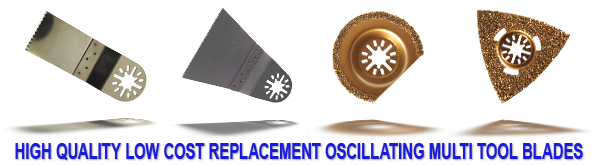

Firstly, it is important to note that oscillating multi tool blades come in different shapes and sizes, which makes them suitable for different tasks. Some of the most common shapes include straight, flush cut, segmented, and circular blades. Each shape is designed to perform a specific task, such as cutting wood, metal, plastic, or drywall.

Straight blades are the most common type of oscillating multi tool blade. They are designed for cutting through wood and other soft materials, such as plastics and fiberglass. These blades are ideal for making long, straight cuts or for removing small sections of material.

Flush cut blades are designed for making precise cuts in tight spaces. These blades have a flat design that allows them to cut flush with a surface, making them ideal for cutting doorjambs or baseboards.

Segmented blades are ideal for cutting through tough materials such as metal, nails, and bolts. They have a serrated edge that allows them to cut through hard materials with ease.

Circular blades are designed for cutting curves and circles in materials such as wood and plastic. They are also useful for cutting holes in drywall or other soft materials.

When choosing an oscillating multi tool blade, it is important to consider the material you will be cutting and the type of cut you want to make. For example, if you are cutting through thick metal, you will need a blade with larger teeth and a stronger construction than if you are cutting through soft wood.

Another factor to consider is the tooth count of the blade. The tooth count refers to the number of teeth on the blade per inch. Blades with a higher tooth count are ideal for making smoother cuts, while blades with a lower tooth count are better for making faster cuts.

Oscillating multi tool blades are an essential component of an oscillating multi tool. They come in different shapes and sizes, each designed for specific tasks. When choosing a blade, it is important to consider the material you will be cutting and the type of cut you want to make. By selecting the right blade for the job, you can ensure that your oscillating multi tool performs at its best and delivers high-quality results every time.