Materials Matter: What Are My Blades Made Out Of?

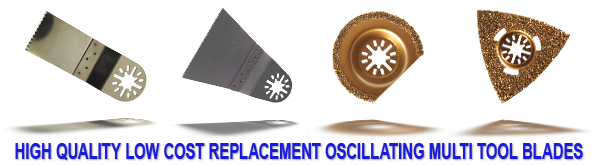

We rely on oscillating multi tool blades for anything from removing grout to shaping wood, but do we know what actually makes them so tough? We’ve all heard the common adage, “Show me what you’re made of,” and now it’s time for these shiny little innovations to do just that. Multi-tool blades are actually made out of a variety of materials known for strength and durability, and understanding these materials can help us select just the right blade for the job.

We rely on oscillating multi tool blades for anything from removing grout to shaping wood, but do we know what actually makes them so tough? We’ve all heard the common adage, “Show me what you’re made of,” and now it’s time for these shiny little innovations to do just that. Multi-tool blades are actually made out of a variety of materials known for strength and durability, and understanding these materials can help us select just the right blade for the job.

The Blade-Making Process

We don’t usually think about this, but oscillating multi tool blades are a form of advanced technology. Each one is carefully planned, including shape, size, and material, to be as powerful as possible. During the blade-making process, metals and alloys (combinations of metals) are processed, melted down into liquid, and poured into molds, where they set into blades. Depending on the blade, a coating of a super-hard substance like titanium or diamond may be applied as well.

Steel

The most common material for oscillating multi tools is steel. Steel does not occur in nature; it is a man-made mixture of iron and carbon, and is formulated to be very hard and resistant to breakage. Because of its strength and versatility, steel is arguably the most pervasive metal in our lives, used in industrial settings, cars, and home appliances, among other products.

The most common material for oscillating multi tools is steel. Steel does not occur in nature; it is a man-made mixture of iron and carbon, and is formulated to be very hard and resistant to breakage. Because of its strength and versatility, steel is arguably the most pervasive metal in our lives, used in industrial settings, cars, and home appliances, among other products.

Since steel is an alloy, there are lots of different varieties that are made depending on what properties are important for the blade. For example, adding more carbon to steel decreases its malleability, but makes it harder and stronger. Carbon steel is probably the most popular choice in blades for this reason.

Stainless Steel

Stainless steel is a variation of steel that contains around 11% chromium. Us normal, everyday people know chromium best as chrome, the really shiny stuff that is used on car door handles and motorcycle piping. Stainless steel is often used to make kitchen knives, surgical equipment, and even some buildings.

Stainless steel is a variation of steel that contains around 11% chromium. Us normal, everyday people know chromium best as chrome, the really shiny stuff that is used on car door handles and motorcycle piping. Stainless steel is often used to make kitchen knives, surgical equipment, and even some buildings.

Aside from making steel shinier and prettier, the addition of chromium to the steel mix makes it even harder and more difficult to wear down. This means that a stainless steel blade will last longer than a carbon steel blade.

Brazed Carbide

Carbide is short in the tool industry for tungsten carbide. This material is actually pretty complicated to make. First, the chemical elements carbon and tungsten are combined to create a powder, which is then squashed together to form metal. The high-tech process is worth it, though: tungsten carbine is twice as hard as steel, and can only be polished with substances such as diamond. Surprisingly, it is becoming increasingly popular in the making of bridal jewelry because of its resistance to scratches.

Carbide is short in the tool industry for tungsten carbide. This material is actually pretty complicated to make. First, the chemical elements carbon and tungsten are combined to create a powder, which is then squashed together to form metal. The high-tech process is worth it, though: tungsten carbine is twice as hard as steel, and can only be polished with substances such as diamond. Surprisingly, it is becoming increasingly popular in the making of bridal jewelry because of its resistance to scratches.

The brazed part of brazed carbide refers to the process of brazing, or combining metals with other metals. This gives brazed carbide blades the gritty texture that allows them to work wonders in removing materials, like grout, from tight corners.

Titanium

Titanium is a natural metal known for its light but strong structure and resistance to damage. It is used in a million ways, including in spaceships and in the military. It is currently being considered as a way to contain nuclear waste.

Titanium is a natural metal known for its light but strong structure and resistance to damage. It is used in a million ways, including in spaceships and in the military. It is currently being considered as a way to contain nuclear waste.

Titanium is somewhat complicated to work with and requires a four-step process in order to be turned into usable products. It is sometimes used to coat oscillating multi tool blades, since just an outer coating of the metal on a steel blade is enough to provide extra edge.

Diamond

Diamond is the hardest natural substance. In fact, the word diamond comes from the Greek word adámas, which means “unbreakable.” Diamonds used for blades and other technology can either come from mines or produced synthetically. Sources suggest that 80% of mined diamonds are not up to par to serve as gemstones and are therefore forwarded on for industrial uses.

Diamond is the hardest natural substance. In fact, the word diamond comes from the Greek word adámas, which means “unbreakable.” Diamonds used for blades and other technology can either come from mines or produced synthetically. Sources suggest that 80% of mined diamonds are not up to par to serve as gemstones and are therefore forwarded on for industrial uses.

Diamond is a notoriously expensive material, and is therefore used to coat blades. However, a diamond coating makes a huge difference in the hardness and the lifespan of your blade. It provides for the hardest and most precise oscillating multi tool blade possible.

Whether your blade is made of steel or coated in diamond, it is nice to know it was specially created to be a hard nut to crack. So use your blades with pride – and don’t forget to impress your buddies with your newfound metallic trivia!